Is All Sharps Waste Incinerated?

You know that horrible moment you realise you’ve burnt the family dinner? That’s nothing compared to burning all of your sharps waste when you don’t need to – just ask the environment!

Thankfully, high-temperature incineration isn’t the only option available for treating sharps waste. Join us as we dig into why it has been the default for so long and how you can secure alternative outlets.

TOPICS WE WILL COVER:

1 / Sharps Waste Incineration: The Traditional Approach

2 / The Hidden Costs of the Sharps Waste Incineration

3 / Why Has Sharps Incineration Been the Default for So Long?

4 / Sharpsmart’s Effluent Retention Process

5 / How the Effluent Retention System Works

6 / What Makes Effluent Retention Different from Other Technologies?

7 / The Bottom Line: Sharps Waste Doesn’t Have to Be Incinerated

8 / Let Your Sharps Waste Help You Achieve Net Zero

Sharps Waste Incineration: The Traditional Approach

For decades, the standard method for treating sharps waste – particularly when contaminated with pharmaceuticals – has been high-temperature incineration (HTI).

The sharps incineration process involves collecting sharps waste in sealed containers, transporting it to a licensed incineration facility, and burning it at temperatures exceeding 1,000°C to destroy pathogens and render the material inert. The resulting ash is often then disposed of in landfill.

Whilst it’s an effective method for neutralising risk, it’s carbon-intensive, resource-heavy, and increasingly unsustainable. It’s also reliant on ageing infrastructure that struggles to meet demand, especially during periods of crisis.

When it comes to sharps waste incineration directives, it’s regulated under the Environmental Permitting (England and Wales) Regulations 2016, the Health Technical Memorandum (HTM) 07-01, and the Waste Framework Directive.

The NHS Clinical Waste Strategy also outlines sustainability targets that encourage alternatives to incineration.

The Hidden Costs of Sharps Waste Incineration

The Hidden Costs of Sharps Waste Incineration

Although incineration has been the go-to treatment solution for sharps waste for so long, it comes with significant downsides.

High Carbon Emissions

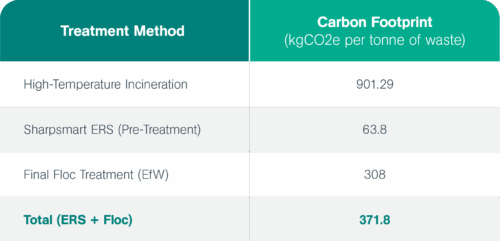

High-temperature incineration produces an average of 901.29kg CO2e per tonne of waste treated, as outlined by the UK Government NAEI Clinical Waste Combustion + BEIS 2021 and used for NHS carbon calculations, including those found in your ERIC data reporting.

Limited Infrastructure

The UK’s incineration capacity is finite and ageing. Building new facilities takes years, and many existing plants are already operating at or near full capacity.

Rising Costs

As demand for incineration increases, so do prices. During the height of the COVID-19 pandemic, some NHS Trusts saw incineration costs double due to limited availability.

No Energy Recovery

Unlike Energy-from-Waste (EfW) systems, many HTI facilities do not recover energy from the combustion process – meaning valuable thermal energy is lost.

So, between its environmental impact, ageing infrastructure and high operational costs, it’s a surprise HTI has been such a popular method for so long.

Why Has Sharps Incineration Been the Default for So Long?

With so many clear disadvantages, you may wonder why incineration has been the go-to method of disposal for sharps waste for so long.

The answer lies in regulation and risk. Sharps waste, especially when medicinally contaminated, is classified as hazardous. This classification has historically limited treatment options to incineration, as it was the only method capable of:

- Destroying infectious agents

- Preventing pharmaceutical residues from entering the environment

- Rendering the waste unrecognisable and unusable

In short, incineration was the only option that ticked all the regulatory boxes – until Sharpsmart developed and patented a new solution…

Sharpsmart’s Effluent Retention System

In response to mountain stockpiles of hazardous clinical waste, a global pandemic, and an ageing waste treatment infrastructure – in 2019, Sharpsmart developed an innovative solution to meet the immediate needs of the healthcare industry. The Effluent Retention System (ERS) – a patented, closed-loop treatment process that offers a sustainable, compliant alternative to high-temperature incineration.

In response to mountain stockpiles of hazardous clinical waste, a global pandemic, and an ageing waste treatment infrastructure – in 2019, Sharpsmart developed an innovative solution to meet the immediate needs of the healthcare industry. The Effluent Retention System (ERS) – a patented, closed-loop treatment process that offers a sustainable, compliant alternative to high-temperature incineration.

Since its invention in 2019, this process has been helping our healthcare partners to:

- Significantly reduce CO2e.

- Have peace of mind with a guaranteed sharps waste outlet.

- Divert high volumes of waste away from HTI.

- Meet and exceed the 20-20-60 waste split set out in the NHS Clinical Waste Strategy.

How the Effluent Retention System Works

Sharpsmart’s ERS transforms hazardous sharps waste into a non-hazardous, unrecognisable material that can be safely used as Solid Recovered Fuel (SRF). Here’s how:

1. Sterilisation

Sharps waste is shredded and sterilised in a controlled environment, neutralising infectious and hazardous agents.

2. Condensing

Steam from the waste sterilisation process is diverted through the Effluent Retention Process and condensed using a ‘non-contact’ heat exchanger and cooling water.

3. Processing

The solid residue (floc) from the plant is processed into a solid recovered fuel, which is used by cement kilns and power plants as a replacement for fossil fuels.

Why This Matters: A 58.75% Reduction in Emissions

Sharpsmart conducted a full carbon footprint analysis of the ERS using NHS and BEIS methodologies. And the results are striking:

That means opting for Sharpsmart’s Effluent Retention System results in a 58.75% reduction in emissions compared to traditional incineration – without having to compromise safety or compliance.

Check Out Our Paper on the Effluent Retention Process

Learn more about our Effluent Retention System and the impressive CO2e reductions it can help you achieve from our paper – The Effluent Retention System: A New Era in Sustainable Sharps Waste Treatment.

What Makes Effluent Retention Different from Other Technologies?

The ERS is the UK’s first system to:

- Treat medicinally contaminated sharps waste without incineration.

- Retain all effluent – no discharge to air or sewer.

- Produce a usable fuel from treated waste.

- Be fully patented and Environment Agency-permitted.

It’s also a fully scalable model that grows with our business and the needs of our healthcare partners, ensuring you always have an outlet for your sharps waste.

The Bottom Line: Sharps Waste Doesn’t Have to Be Incinerated

Sharpsmart’s Effluent Retention System proves that compliance, safety and sustainability can go hand in hand. It’s a smarter, cleaner and more resilient way to manage sharps waste – one that’s already making a measurable difference across the UK healthcare system.

Environmental Impact

The ERS significantly reduces carbon emissions and diverts waste from fossil-fuel incineration – supporting Net Zero goals and the 20-20-60 waste split.

Operational Resilience

By reducing reliance on ageing incineration infrastructure, the ERS helps prevent service disruptions and stockpiling during periods of high demand.

Regulatory Compliance

The system meets all Environment Agency requirements and is fully compliant with UK waste treatment regulations.

Future-Proofing

The ERS is retrofit-ready and designed to scale – making it a long-term solution for sustainable sharps waste treatment.

Let Your Sharps Waste Help You Achieve Net Zero

Whilst there are many sharps waste incineration companies in the UK, none are known for helping you use your sharps waste as a tool on your Net Zero journey, other than Sharpsmart.

We’ve been dedicated to increasing sustainability and developing greener solutions in the healthcare waste industry for over 24 years – partnering with hospitals throughout the UK to reduce carbon emissions with proven results.

When it comes to reducing your carbon footprint, we’ve got you covered.

Take your next step towards Net Zero and a greener future for the healthcare industry.

Let's Talk!

Your time is valuable, and we don’t want to play hard to get. You can either phone us directly on the details listed on our contact page, or feel free to fill out this short form and one of our team members will get back to you as quickly as possible.